Industry 4.0 is here now, and Maxim’s Pocket IO PLC development platform shows how it can reinvigorate manufacturing operations with tiny sensors and distributed control units.

The Industry 4.0 movement is at an inflection point with connected sensors meeting the assembly line to facilitate adaptive manufacturing, distributed control, and real-time decision-making in harsh factory environments.

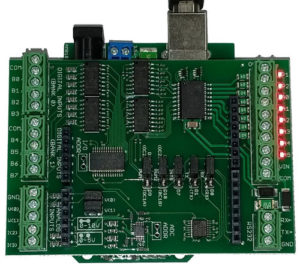

Maxim Integrated is pushing the Industry 4.0 envelope with its Pocket IO PLC development platform that encompasses industrial power, digital isolation, digital input and output, I/O link, and encoders and motor drivers.

The reference design—which includes the attach board, IO-link protocol stack, cables, and power supply—is smaller than its predecessor Micro PLC platform and dissipates far less heat.

Jeff DeAngelis, Managing Director of Business Management at Maxim Integrated, says that manufacturers are already seeing the benefits of products centered around Industry 4.0, especially in the countries that are re-engaging in the manufacturing business, saying “The Pocket IO PLC design platform creates a pathway to Industry 4.0 by bringing compact PLCs to manufacturing line.”

According to a recent report from Price Waterhouse Coopers (PwC), Industry 4.0 is no longer a future trend. The report says that 35% of companies adopting Industry 4.0 expect revenue gains over 20% over the next five years.

Evolution of Industrial PLCs

The programmable logic controller or PLC—which could only fit in a large room during the 1970s and was of closet size during the 1980s—has become smaller and more compact over the years while reducing the amount of heat it generates. Now, Maxim has put the 9.8 cubic-inch Pocket IO PLC reference board in developer’s pocket.

In 2014, Maxim launched the Micro PLC platform that used more than 50 ICs, encompassing analog and digital I/Os, communication channels, and industrial-grade power devices. Maxim claims that the Pocket IO PLC has decreased form factor by 2.5x and has reduced power consumption by 30%.

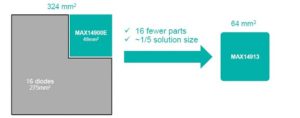

For a start, Maxim has shrunk the size of digital output modules with the availability of a faster octal high-side switch and driver, AX14913. It facilitates 15x space savings by eliminating 16 diodes from its previous solution: MAX14900E in the Micro PLC platform. Next, for I/O link sensor, Maxim is replacing the 4mm 2 MAX14826 chip, which dissipates 400mW, with 2.5mm 2 MAX14827 chip that generates merely 180mW.

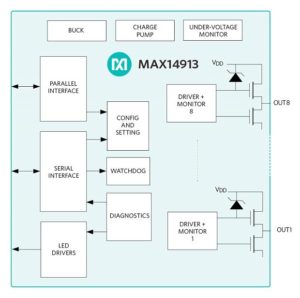

The MAX14913 octal high-side switch and driver provides ultra-high speed switching and safe demagnetizing clamps, and can reliably interface low-voltage digital signals to 24V output-control lines. Maxim claims it’s the industry’s smallest octal high-side driver that enables compact, high-density I/O modules while reducing board space by 40% compared to other solutions on the market.

The engineers developing PLCs, motion control units, drives, and other industrial and process automation applications need a high-side switch to control inductive loads. The MAX14913 chip can discharge and demagnetize any inductive load safely using integrated clamps. Moreover, it provides diagnostics on open- and short-circuit load lines, the most common external failure mode.

Maxim is showcasing the MAX14913 chip, the Pocket IO PLC development platform, and other Industry 4.0 solutions at the electronica 2016 show being held in Munich, Germany on November 8–11, 2016.

Source: http://www.allaboutcircuits.com/news/plc-design-board-aims-at-industry-4.0-applications/